Last Updated on August 30, 2023 by tech pappy

Hello there, tech enthusiast! Welcome to the right place on the internet if you are fascinated with 3D technology. With technological advancements, the world is embracing the third dimension in various fields.

Through innovations like 3D models and 3D printing, we’re experiencing a paradigm shift in how we create and manufacture products.

Understanding 3D Printing Technologies and Processes

Overview of Additive Manufacturing

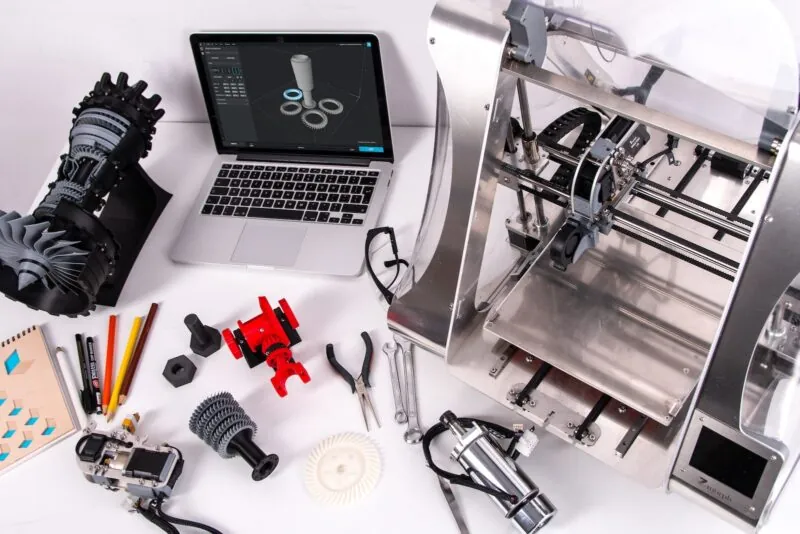

3D technology is an additive manufacturing process that creates three-dimensional objects layer by layer from a digital CAD model.

This process allows for rapid prototyping and production of complex designs, which were previously impossible or time-consuming to produce with traditional manufacturing methods.

Additive manufacturing enables the creation of customized and intricate designs with minimal material waste.

Types of 3D Printing Technologies

There are several types of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

FDM printers heat and extrude a thermoplastic filament layer by layer to create a 3D object. SLA printers utilize a UV laser to solidify a liquid resin, while SLS printers use a laser to fuse a powdered material, like metal, plastic, or ceramic.

Each technology has advantages and drawbacks depending on the application and materials used.

Common 3D Printing Processes and Materials

The most common 3D printing processes include turning a CAD model into a 3D printable file, preparing the print bed, and setting up support structures if required.

3D printing materials vary depending on the technology used, and they can range from plastic-like materials (PLA, ABS) to metal 3D printing alloys (stainless steel, titanium), ceramics, and even food materials.

Some materials require post-processing to achieve desired mechanical properties or appearance.

Creating 3D Models: What You Need To Know

Introduction to 3D Modeling Software

3D modeling software enables enthusiasts and professionals to create and sculpt digital 3D models. Many options are available, from beginner-friendly tools like Tinkercad to advanced programs like Blender or SolidWorks.

Selecting the right software depends on the user’s proficiency, goals, and application of the 3D model – whether for 3D printing, animation, or engineering.

Creating Your First 3D Model

Starting a journey into 3D modeling often begins with learning a software package’s tools and features. Most programs offer tutorials or guided lessons in building a simple 3D model.

As users progress, they can move on to more complex models and incorporate 3D scanning, photogrammetry, or even pre-built assets from marketplaces and libraries.

Optimizing and Preparing Models for 3D Printing

A 3D model to be 3D printable, it needs to be optimized and prepared for the specific technology used in 3D printing.

This process involves checking for errors in the CAD model, ensuring correct dimensions and resolution, and adding support structures if needed.

It may also involve adjusting the print settings, such as layer height or infill density, to optimize the final 3D printed product’s quality and strength.

Choosing the Right 3D Printer for Your Needs

Comparing Different Types of 3D Printers

Selecting the right 3D printer depends on multiple factors, including the desired application, material, and budget. When comparing different types of 3D printers, it’s essential to consider print volume, resolution, speed, and required maintenance.

Each technology has unique characteristics that cater to different use cases – from at-home hobbyist projects to industrial-scale manufacturing.

Understanding Printer Specifications

When buying a 3D printer, it’s crucial to understand its specifications, such as build volume, layer height, print speed, and material compatibility.

These specifications dictate the printer’s capabilities and give a clear picture of what can be achieved with the machine.

Other considerations must be considered, such as noise levels, connectivity options, and software compatibility.

Considerations for Home and Professional Use

A 3D printer for home use may prioritize ease of use, affordability, and safety features. At the same time, professional users may need a more robust machine capable of handling advanced materials with high resolution and speed.

In both cases, considering workspace requirements, post-processing needs, and ongoing expenses like material and maintenance costs are equally essential in making an educated decision.

Diving into the 3D Printing Industry and Applications

Growth and Trends in the 3D Printing Industry

The 3D printing industry has seen exponential growth in recent years, fueled by technological advancements, adoption by various industries, and increased accessibility for consumers.

On-demand 3D printing services, bioprinting, and mass customization are some of the significant trends disrupting traditional manufacturing and driving innovative applications.

Industries Transforming with 3D Printing

Many industries have undergone transformations through 3D printing, such as automotive, aerospace, healthcare, fashion, and construction.

3D printing allows for customized, lightweight, intricate parts, rapid prototyping, and on-site construction. This technology has also paved the way for breakthroughs in medical devices and implants or accessible custom-made prosthetics.

Innovative and Practical Applications of 3D Printing

From 3D printed cars to bespoke fashion pieces, 3D technology has opened the doors to various practical and innovative applications.

These can include rapid disaster relief through on-site construction, personalized and patient-specific medical treatments, or eco-friendly solutions like recycling plastics into new 3D-printed parts.

Exploring the Future of 3D Systems and Technology

Advancements in 3D Printing Materials

Continued research and development efforts in 3D printing have led to more advanced and diverse materials.

These advancements range from high-performance or biodegradable plastics to enhanced metal alloys and even multi-material printing, opening the doors to many possibilities regarding product design and functionality.

Breakthroughs in 3D Printing Processes

As the 3D printing industry evolves, new processes and techniques are emerging, such as binder jetting, which eliminates the need for support structures, or the Continuous Liquid Interface Production (CLIP) technology, which decreases print times dramatically.

These breakthroughs promise to improve the overall efficiency and capabilities of 3D printing in multiple applications.

Emerging Technologies and Their Potential Impact

Emerging technologies like AI-driven design optimization, virtual and augmented reality for 3D design, or even 4D printing (where printed objects change shape over time) can revolutionize how we approach 3D technology.

Fusing these innovative technologies with existing 3D systems promises to unlock new possibilities and transform how we create and interact with the physical world.